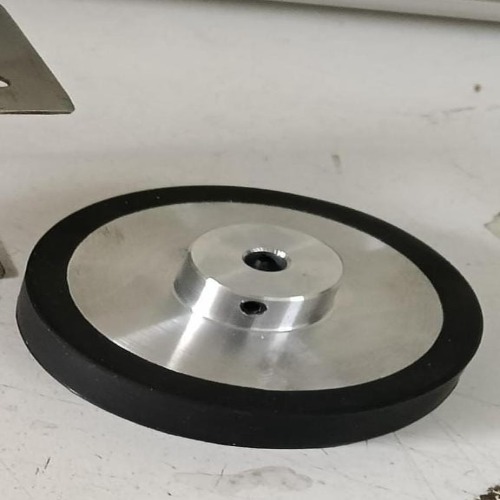

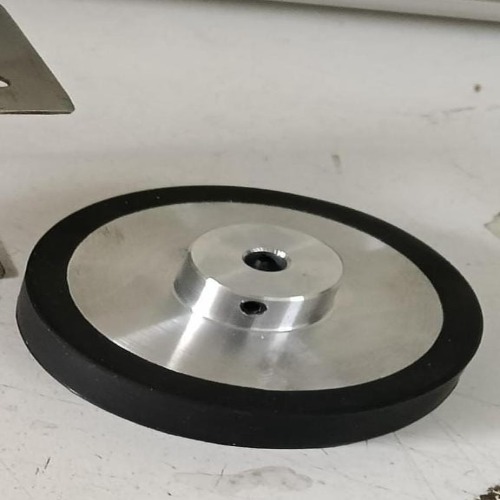

About RUBBER COATED MEASURING WHEEL

- Structure:It consists of a central hub (often made of aluminum or other metals) and an outer layer of rubber, which provides the contact surface for the abrasive belt.

- Function:The rubber contact wheel provides support and pressure for the abrasive belt, allowing it to conform to the workpieces shape during grinding, sanding, or polishing.

- Material:The rubber tread can vary in hardness (e.g., Shore A hardness) and contour (e.g., smooth, serrated, or grooved) depending on the specific application and desired finish.

- Applications:Commonly used in metalworking, woodworking, and other industries for tasks like surface grinding, deburring, chamfering, and achieving specific finishes on various materials.They are also used in encoder systems to track movement and ensure precise timing in applications like batch coding and labeling.

Versatile Industrial ApplicationsThe Rubber Coated Measuring Wheel excels across diverse industries, including metalworking, woodworking, and manufacturing. Its design enables it to support activities like grinding, deburring, and chamfering with enhanced precision. It also plays a vital role in encoder systems, ensuring accurate timing for batch coding and labeling, which boosts productivity and efficiency.

Quality Construction with Reliable WarrantyCrafted from high-grade rubber, this measuring wheel is built to withstand demanding environments yet maintain accuracy over time. The one-year warranty offered by the manufacturer underscores a commitment to durability and customer satisfaction, making it a dependable choice for industrial tasks.

FAQs of RUBBER COATED MEASURING WHEEL:

Q: How can a rubber coated measuring wheel benefit industrial applications?

A: The rubber coated measuring wheel enhances grip, provides accurate measurements, and reduces slippage, making it suitable for processes like grinding, deburring, and chamfering in metalworking and woodworking. Its precision tracking also improves batch coding and labeling tasks.

Q: What is the main function of the rubber coated measuring wheel in encoder systems?

A: In encoder systems, the measuring wheel plays an essential role in tracking movement and maintaining precise timing, which is crucial for applications such as batch coding, product labeling, and automated industrial processes.

Q: Where is the rubber coated measuring wheel commonly used?

A: This measuring wheel finds application in metalworking, woodworking, and various manufacturing industries where operations like surface grinding, deburring, and achieving specific finishes require reliable measurement tools.

Q: When should I consider replacing my rubber coated measuring wheel?

A: You should consider replacement when signs of wear such as reduced grip, cracks in the rubber coating, or declining measurement accuracy become evident, especially after extensive industrial use.

Q: How is quality assured for these measuring wheels?

A: Quality is ensured through the use of durable rubber material and stringent manufacturing standards. Added confidence comes from the one-year warranty provided by the supplier or manufacturer.

Q: What is the manufacturing origin of these measuring wheels?

A: These rubber coated measuring wheels are manufactured and supplied in India, adhering to high quality standards and industrial requirements.